Stacked “Vertical” Farming Doesn’t Stack Up

“Indoor farming” is an umbrella term for many different farming technologies, with very different characteristics. Indoor farms today are predominantly greenhouses, whose technology has matured over several centuries. Vertical farming is still in its infancy and was developed to meet a need greenhouses and field agriculture fundamentally cannot: growing a steady supply of fresh produce year-round, anywhere in the world.

Indoor vertical farming must scale massively to impact the global food supply. As the vertical farming industry works to move from the startup to scale-up stage, we predict there will be a shakeout between “stacked tray” vertical farms and truly vertical farms. Why? The claimed benefits of stacked-tray vertical farming simply don’t stack up. It’s basic physics. And it’s going to lead to more failures in the “vertical” farming space in the coming months and years.

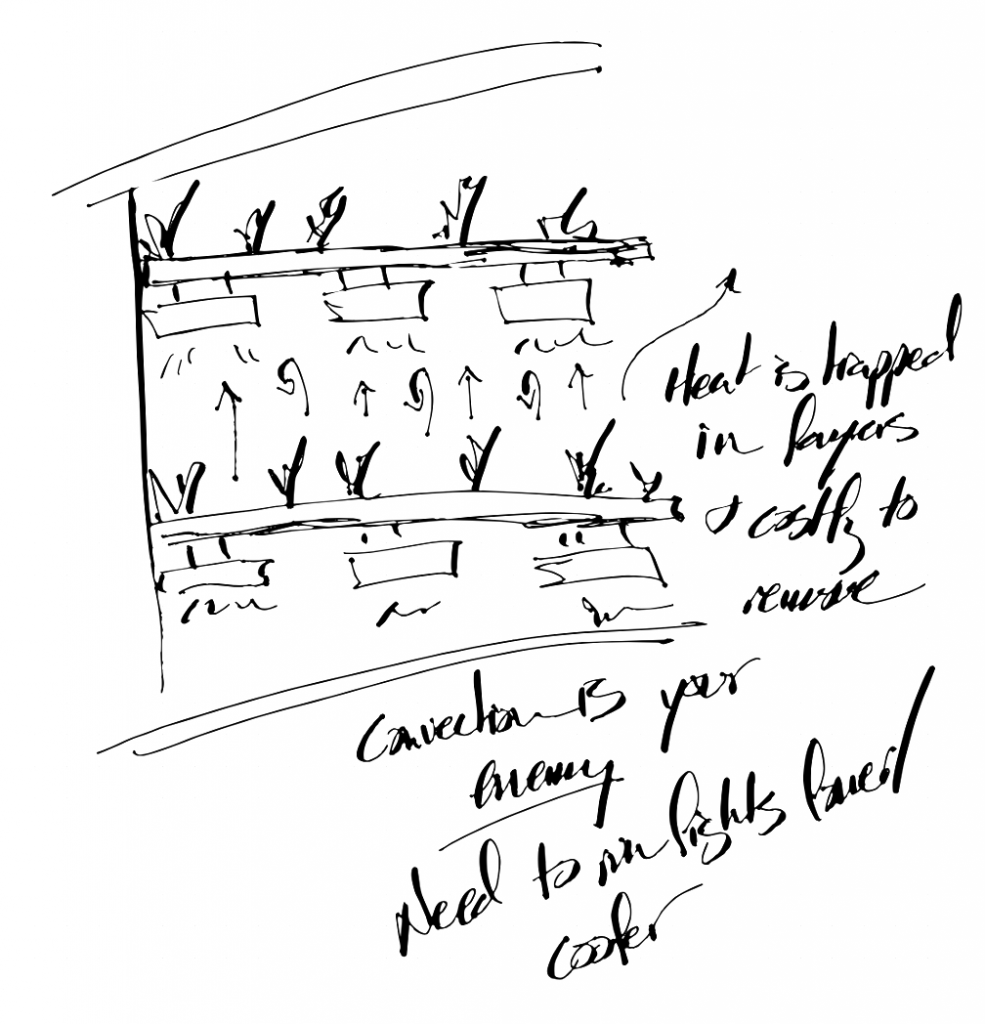

Heat is trapped in layers + costly to remove. Convection is your enemy. Need to run lights lower/cooler.

The “stacked tray vertical” approach grows plants horizontally in trays that are then stacked vertically on top of each other to make better use of floor-to-ceiling space than greenhouses. This approach is not a first principles approach – it simply takes something that already exists and stacks it. The first big problem with that approach is that stacked trays trap heat. That limits the intensity of the lights that stacked vertical farms can use, which puts a cap on yield since more light equals more photosynthesis, which equals more yield. As a result, stacked vertical farms have limited levers to pull to increase yields. With gains limited to the efficiency improvement rate of LEDs, their unit economics are challenging and there’s limited likelihood of running profitable farms. The second big problem is that the spatial efficiency of stacked tray systems is low – because it takes more surface area under lower light to produce the same amount of produce as the same surface area under higher light, and because human access requirements are higher and plant densities are fundamentally lower. Lastly, stacked tray systems struggle to support crops outside of leafy greens at mass commercial scales.

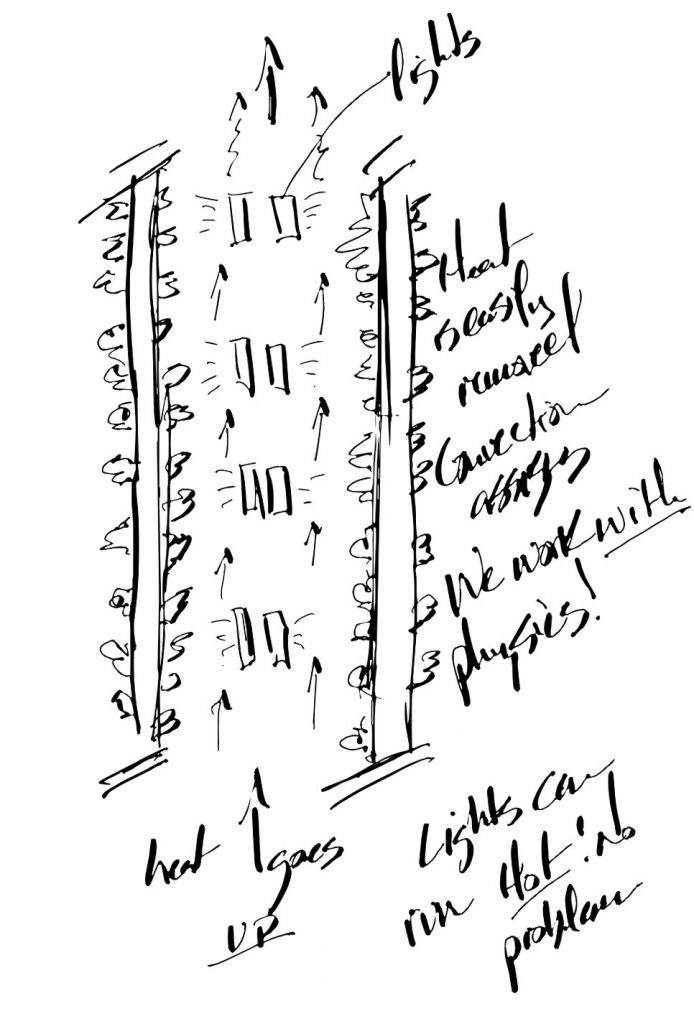

Heat is easily removed. Convection assists. We work with physics! Heat goes up. Lights can run hot! No problem.

By contrast, a “true” vertical approach changes the orientation of the growing plane. True vertical farms maximize the density of plants in a three-dimensional space by growing on massive, uninterrupted vertical growing planes, placed back to back (in Plenty’s case, on both sides of vertical grow towers nearly two stories high). This enables much more production area in the same volume of space as single-sided stacked tray systems. Plenty’s true vertical system generates up to 6X more yield than stacked tray vertical growing systems per square foot of grow room as a result. By growing truly vertically, we can use lighting that is more intense than stacked-tray competitors. Ultra-intense lighting is a key driver of that hyper-yield, and we can exponentially increase our yields by increasing the power of our lights. Air circulation in wide vertical aisles (that double as access) is efficient, simple and assisted by convection. Plenty’s true vertical system has a modular, flexible architecture that can support a wide variety of plants and introduce crop diversity. We’re the only true multi-crop platform in indoor ag, assisted by the precise temperature and humidity control we have over our environment. Stacked tray vertical farming cannot match the control and the resulting yield and quality across an assortment of crops. Vertical plane system architecture enables platform, quality and yield in the most fundamental of ways.

Vertical farming has to branch beyond greens to address unmet market needs and support both food security and nutrition security. To meet those needs, more caloric crops need to be vertically grown at commercial scale and at a price point that’s competitive with field-grown counterparts.

Plenty can grow the widest array of high-value, nutrient-rich crops of any indoor farm by far – we’ve grown more than 50 different crops and 1,400 cultivars in our vertical growing system so far. The first proof point? We’re dedicating our next farm (opening in 2024) to strawberries.

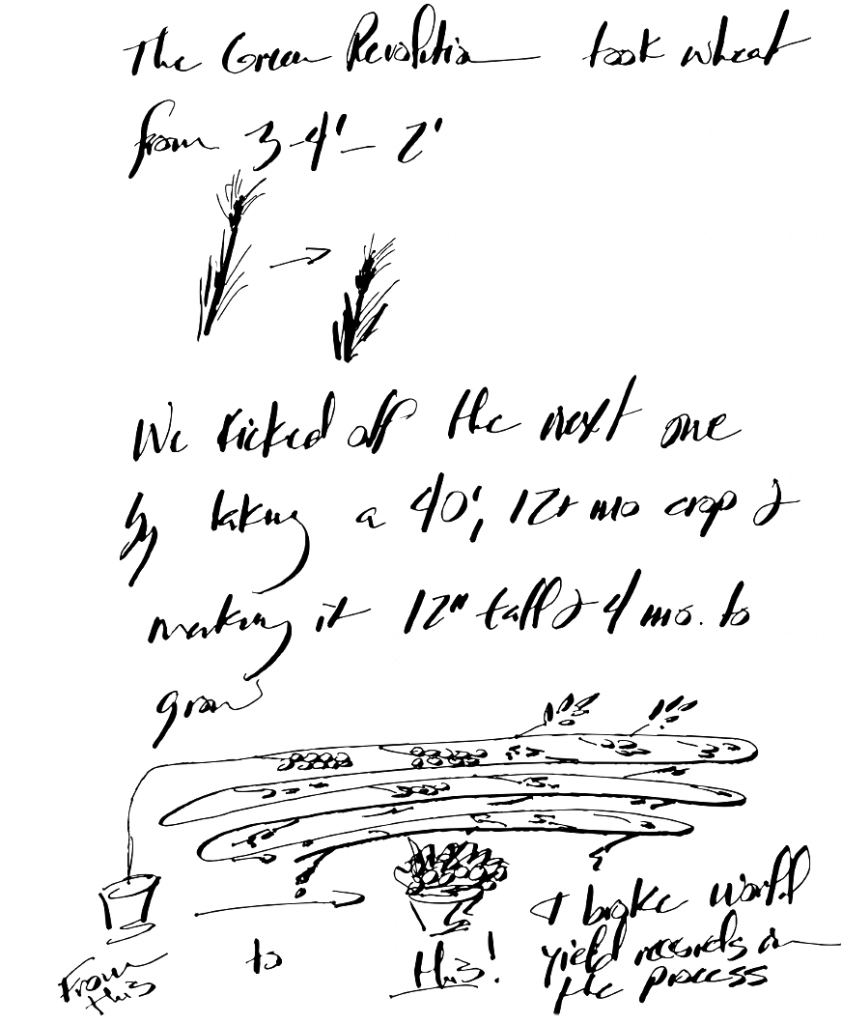

The green revolution took wheat from 3-4’ to 2’. We [Plenty] kicked off the next one by taking a 40’, 12+ mo crop + making it 12” tall + 4 mo to grow. From this to this! + broke world yield records in the process.

We made the choice to commercialize strawberries for a number of strategic reasons:

- The true total addressable market (TAM) for strawberries is unknown because market demand exceeds supply. This gap is created by the fully utilized but insufficient land on Earth that is suitable for producing high-quality strawberries economically, so Plenty will manufacture the best ag land in the world, anywhere in the world, to meet this demand.

- Strawberry quality and pricing fluctuates dramatically throughout the year, whereas production in our farms can be constant and predictable in terms of quality and cost.

- Out-of-season berries are often shipped halfway around the world to reach consumers, with an unexpected impact on quality. Growing strawberries better than the best land, anywhere in the world is a dramatic demonstration of what indoor agriculture can do for local production and food security.

- Plenty is able to do something other indoors farms can’t – grow berries at commercial scale with positive unit economics, all enabled by our architecture, investments in R&D, and the dramatic technology cost curve that we have bought with these investments.

Plenty is on a completely different path than stacked tray vertical architecture companies that lack a scalable path forward beyond greens. By investing hundreds of millions of dollars into R&D, we have uniquely developed a modular, flexible growing architecture that can support a vast array of plants at densities and yields that are unmatched by any other approach. The capabilities born of that architecture have positioned us to weather this storm and grow into the future, across new crops, geographies and economics.